Photonic integrated circuits (PICs) are an emerging technology field that can offer low energy consumption, fast operation, and enhanced performance with respect to bulk optical systems. However, current PIC fabrication methods lead to a large variability between fabricated devices, resulting in limited yield, long delays between the conceptual idea and the working device, and a lack of configurability. TU/e researchers have devised a new process for the fabrication of PICs that addresses these critical issues – by creating novel reconfigurable PICs.

Current programmable PIC concepts suffer from issues such as volatility and/or high optical signal losses – both of which negatively affect material’s ability to keep its programmed state. Using hydrogenated amorphous silicon (a-Si:H), a material originally developed for thin-film silicon solar cells, TU/e researchers have designed a new PIC fabrication process that addresses these shortfalls of current techniques. They reported on this process in the journal Advanced Optical Materials.

According to Oded Raz, Associate Professor at the Electro-Optical Communications group of the Department of Electrical Engineering and research lead of this project, this approach could be of paramount importance for the field of PICs. ‘This is the world’s first demonstration of a reconfigurable PIC, where the material chosen for making the integrated optical circuit is being programmed.’ This revolutionary new approach has further advantages. ‘Most importantly, in comparison to current methods, the time to prototype is much shorter and much more accurate’, says Raz.

Heaters can be placed on a pre-light exposed device to allow the user to program a PIC device as desired. The same heaters can also reset the device and return it to a state that can be easily reprogrammed. ‘This approach allows the user to easily program the functionality of a PIC and to concurrently correct for small errors in the fabrication process,’ says Raz.

Polymer coating

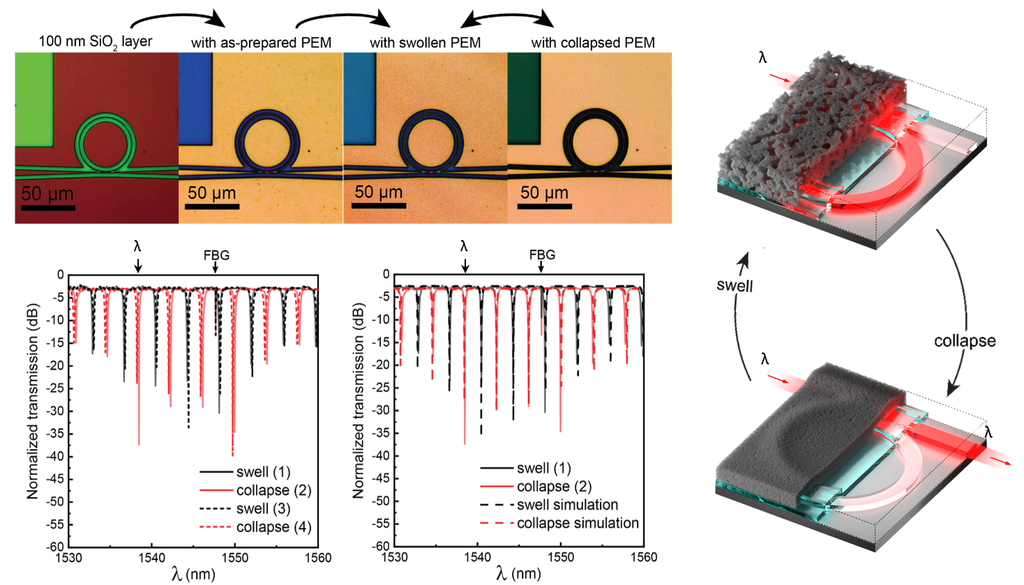

In a second approach, reported in a second article in the same journal, the researchers from the department of Electrical Engineering teamed up with the department of Chemical Engineering and Physics to develop a new and non-traditional polymer-based approach. This approach significantly reduces the programming time and increases the programming possibilities for PICs. The novel fabrication method involves coating photonic materials with a specific polymer. The optical properties of the polymers can be widely tuned in a matter of minutes using acidic solutions of varying pH.

This new approach offers a wide range of control and flexibility when it comes to producing programmable photonic devices. Importantly, devices can be programmed in a matter of minutes using the polymer approach. And even more impressively, the programmed state is non-volatile and stable, based on observations made in the first six months following the programming.

“We are well on our way to adding photonic capabilities to electronics, which will revolutionize the microelectronics industry.”

Oded Raz | Associate Professor

Raz: ‘This entirely new direction for making reconfigurable photonics paves the way for the low-cost mass production of reprogrammable PICs. These two exciting demonstrations are just the start of a new research direction which requires multidisciplinary collaboration. The interaction with physicists and chemists frees me as an electrical engineer to put forward requirements on the materials properties without being tied to any constraints. On the other side of the equation, the physicists and chemists I have had to pleasure to work with, are finding new exciting uses for materials which have lost their “shine”.’

The ultimate target, on which Raz and his team are currently working together with Prof. Ilja Voets and Prof. Rint Sijbesma from the Chemistry department, is a coating that can be controlled using a stimulus such as heat, electric field or light which can be integrated on the chip.

More information: https://onlinelibrary.wiley.com/doi/abs/10.100

2/adom.202070022

Revolution: light-emitting silicon

Reprogrammable photonic integrated circuits

Integrated nanometer scale sensing